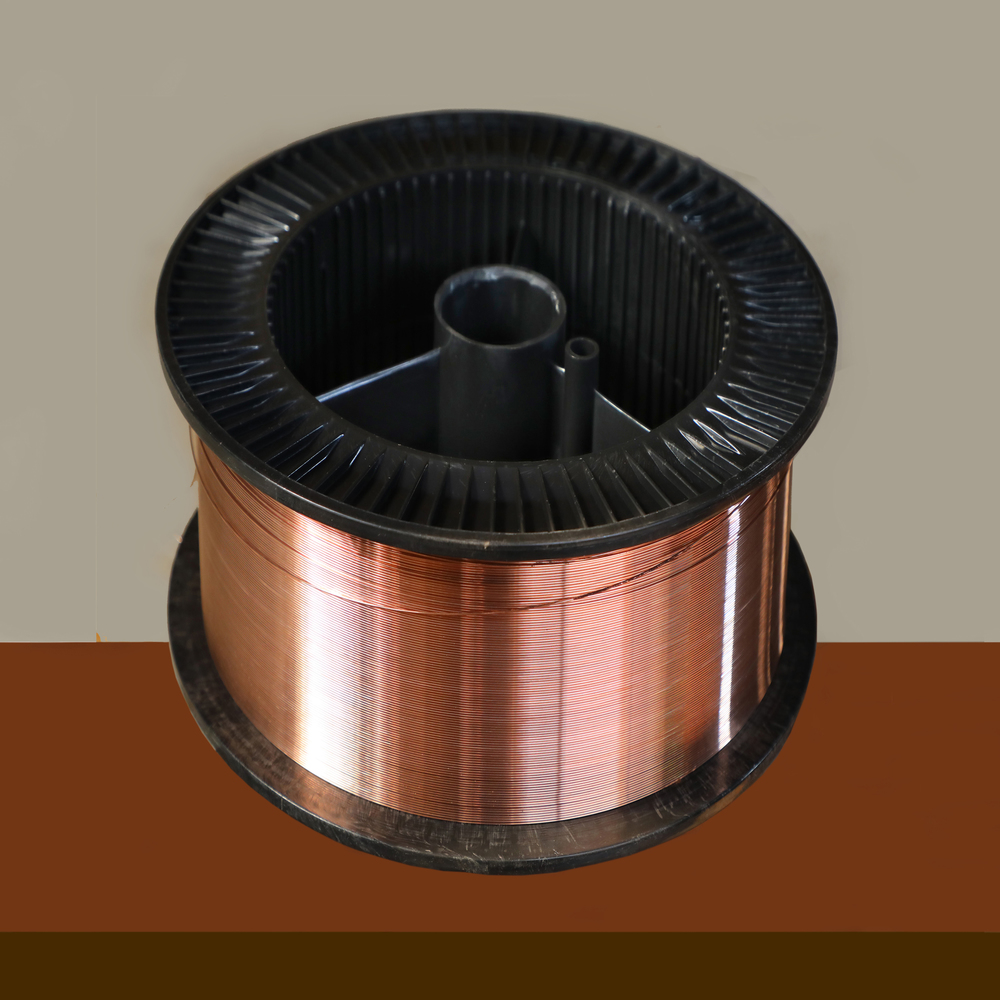

Metal Inert Gas (MIG) welding is a gas metal arc welding (GMAW) process that uses a continuous solid wire electrode which is heated and fed into the weld pool from a welding gun.

MIG is an attractive alternative to MMA, offering high deposition rates and high productivity

When it comes to MIG welding, it uses a combination of heat and an electrode wire to create a molten pool to fuse two pieces of metal together.

In MIG welding, you can easily join a variety of metals, and the type of wire used is determined by the type of metal being welded.

| Tensile strength (Min) |

Yield Stress (Min.) |

% Elongation At GL = 5.5 √50 |

Impact Energy Charpy V notch At 20°C |

|---|---|---|---|

| 500 N/mm2 | 420 N/mm2 | 22 Min. | 27 Joules Min. |

| Size of wire (mm) | Current Amps (DC) | Volts | CO2 Gas flow (lt/mm) |

|---|---|---|---|

| 0.80 | 50-160 | 20-30 | 10-15 |

| 1.00 | 80-200 | 20-30 | 12-20 |

| 1.20 | 120-280 | 22-40 | 15-25 |